Buying a roller coaster is a major commitment for any amusement park or carnival. But while thrill, size, and appearance often take the spotlight, it’s the manufacturer’s reputation and safety practices that truly determine a ride’s long-term value. As high-speed attractions, roller coasters (аттракцион американские горки) must meet the highest safety standards to protect guests and ensure operational success.

In this article, we explore why choosing a reliable manufacturer is the foundation of a successful roller coaster investment—and how that decision impacts the overall performance of your amusement rides, from coasters to Ferris wheels and even disco rides.

Understanding The Importance Of Supplier Credentials

Not all ride manufacturers are created equal. Some specialize in large-scale thrill rides, while others focus on portable models or rides for children. When purchasing a roller coaster online, one of the most crucial things to examine is whether the manufacturer has proper certifications and complies with international standards such as ASTM, EN, or ISO.

These certifications are more than formalities—they reflect the company’s commitment to quality engineering, risk reduction, and transparent practices. The right partner will have a clear track record in producing safe, durable amusement equipment that can withstand years of heavy use.

How Safety Engineering Impacts Guest Experience

Even the most impressive roller coaster design loses its appeal if it fails to prioritize rider safety. Each curve, drop, or loop must be carefully engineered with predictable forces, adequate restraint systems, and emergency mechanisms in place.

Reputable manufacturers invest in rigorous pre-delivery testing, including both static and dynamic trials. This ensures the roller coaster functions exactly as planned under various loads and conditions. Additionally, companies that offer safety audits, maintenance guides, and training add considerable value.

This is especially relevant in mixed-ride venues, where attractions like Ferris wheels and disco rides (диско аттракцион) coexist with coasters. A safety-centered manufacturer understands how different ride dynamics interact in a shared space and can help you plan accordingly.

The Long-Term Cost Of Poor Quality Control

Upfront savings might seem attractive, but cutting corners on manufacturing quality can lead to costly repairs, downtime, or even legal issues in the long term. A poorly made roller coaster will likely suffer from frequent mechanical failures, inconsistent performance, and increased safety risks.

On the other hand, trusted manufacturers use premium materials, perform thorough inspections, and offer warranty-backed components. These elements reduce the chances of technical malfunctions and contribute to the reliability your business needs.

Amusement parks that buy rides with long-term performance in mind often see higher return on investment. That’s because visitors come back—not just for the thrill, but for the trust and consistency that premium rides provide.

Identifying A Brand With A Proven Portfolio

Before making a purchase, take time to research the manufacturer’s previous projects. Has the company delivered successful installations in other regions? Do they have a presence in major parks, festivals, or international expos?

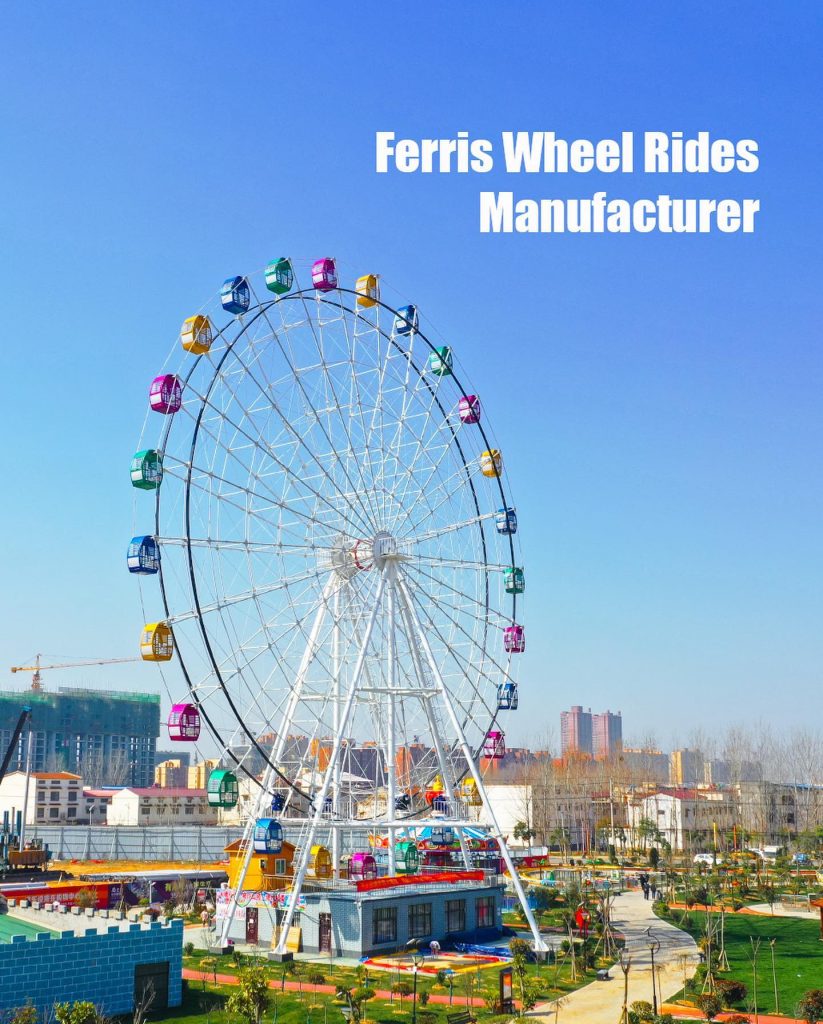

Look for case studies or client testimonials that describe how the roller coasters performed under real-world conditions. Also explore whether the same manufacturer supplies other well-known attractions like Ferris wheels (колесо обозрения купить) or disco rides. A diverse product line often reflects extensive design expertise and reliable production capacity.

A credible supplier will not only show off their achievements but also be transparent about product capabilities, limitations, and the services they provide after the sale.

The Role Of After-Sales Support And Technical Training

Another often-overlooked aspect of choosing a manufacturer is the availability of ongoing support. Roller coasters require regular inspections, software updates (for modern digital systems), and preventive maintenance to stay operational.

Manufacturers that offer installation guidance, spare parts availability, and staff training give you a significant advantage. They also make troubleshooting easier when unexpected issues arise, especially for seasonal operators or new amusement park owners.

You should always ask whether the supplier provides remote diagnostics, technical documentation, or in-person support before committing to any purchase. These services contribute directly to the ride’s reliability, longevity, and safety.

Making The Smart Choice For All Ride Types

While roller coasters are often the star attraction, smart park operators apply the same manufacturer selection standards to other rides (виды аттракционов) as well. Whether you’re planning to install a Ferris wheel for panoramic views or disco rides for spinning excitement, the principles of safety, quality, and brand reliability still apply.

Experienced manufacturers know how to balance mechanical design, guest comfort, and regulatory compliance across their entire catalog. Working with one trusted vendor for multiple rides can also simplify logistics, reduce costs, and create a cohesive brand experience within your venue.

Conclusion: Trust Is The True Foundation Of Thrill

A roller coaster is more than steel and speed—it’s a symbol of excitement, engineering, and guest trust. Choosing the right manufacturer ensures that every ride is thrilling for the right reasons, not stressful due to quality issues or safety concerns.

By focusing on the supplier’s track record, certifications, safety philosophy, and post-sale support, you’ll be investing in more than just an attraction. You’ll be building a lasting partnership that helps your amusement park thrive—whether you’re expanding with new roller coasters, iconic Ferris wheels, or crowd-pleasing disco rides.

In the fast-paced world of amusement entertainment, safety and trust are the real thrill factors—and they start with the right manufacturer.