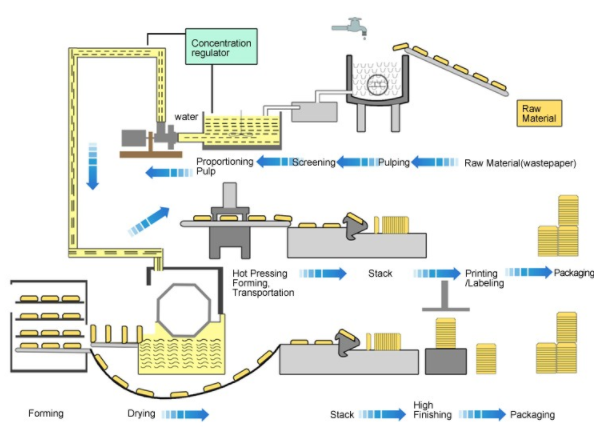

The production line of a basic egg tray making machine is actually quite extensive. It’s even more complex if you are looking at one that is fully automated. There are several different aspects to this product line which will include the pulping system, the pulp forming equipment, which is called the drying system and even the section to pack egg trays together. Essentially, every one of these is going to have a minimum of the first three components. The pulp must be made, formed, and subsequently produced into the trays that are used. Let’s go over each of these in detail so that you can understand what to look for if you are going to invest in one of these units.

Pulping System

This is a system by which different materials, preferably recycled materials, can be converted into the pulp that is used. This could be anything from cardboard to newspaper, and other types of paper products, all of which can be created into this pulp that can be poured. The larger the system, the more time it’s going to take to make an entire batch. However, the larger it is, the better off you will be, especially if your business decides to expand. Beston Machinery will be a good option for you. Here is the website: https://bestoneggtraymachine.com.

Forming System

This is where the machine is actually the most prevalent. It is the part where the pulp is placed into trays, and they are formed into various pulp molded products, such as egg cartons, that you are going to use. These are typically spherical, although shaped with sharp edges, and it will rotate as the pulp is added to the system. Once this is done, you will then have the trays come out and they will go into the drying system.

Drying System

The drying system is an important part of an egg tray production line. This is where it will go into the oven. It should be able to hold multiple trays, allowing them to be dried as quickly as possible. The larger the oven, the more trays you are able to produce. These are typically very long, allowing them to move through the system on a conveyor belt, and come out the other side completely solidified. From there, workers will then separate the trays from the egg trays, and everything can be stacked and ready to use.

The larger the system, the higher the probability that you will be able to produce enough trays for not only yourself but other companies. At the end of your search, you will know that you have found the best business based upon the quality of the trays and how many you can produce. If you can find great feedback on these, you should spend a little time evaluating each company until you find the right one. Consider your budget, but also consider the long-term ramifications of using one better egg tray manufacturing machine that uses a complete and automated production line. As long as you have looked at each of the top companies in China, you will end up with one that is going to provide you with exceptional products at the most affordable prices available.