In many parts of the world used tires have been piling up for decades. Sometimes they catch fire and burn for years releasing toxic fumes and poisoning the local inhabitants. Other times they fill with water and breed mosquitoes that harbor diseases like Malaria that are dangerous to residents living nearby. Now there is a new process called waste tire to oil technology that can not only eliminate the huge piles of waste but can also make a profit from the components while protecting the environment as well.

The Pyrolysis Process Works On Tires, Waste Oil, And Plastics

Tires are a huge problem for several reasons, first, they don’t stay buried in landfills because they’re constantly rising to the top, they won’t biodegrade for nearly 1,000 years, and if they catch fire they’re toxic.

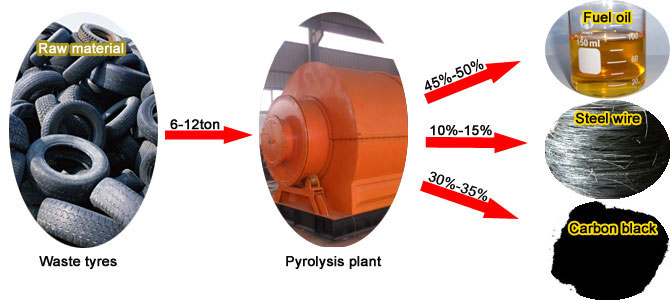

One of the great advantages of a tire pyrolysis plant is that it can take care of the tires cleanly. It doesn’t emit toxic fumes, and the waste components left over are easily usable or sellable on the open market. The process works quite well on rubber tires, plastics, waste oils, and even some agricultural waste as well.

The reason the process works without creating pollutants is that it starves the process of oxygen which inhibits ignition. Basically, without oxygen, there is no fire, so the tires break down and decompose into basic ingredients such as fuel oil, gas, and carbon black. Learn more about the tire pyrolysis plant design here.

The Fuel Oil Is About 40% By Weight Of The Tires

When the tires are heated to about 500 degrees they start to break down. The oils and gases are first all released as gases, then when they go through the condensation process, the oils cool down and are separated. Most pyrolysis machines will divide the different oils into light, medium, and heavy because each one can be sold to a different industry that way.

Many industrial process use fuel oil as a way to head ingredients when combining them chemically and the heavy oil is fine for that. The lighter oils can be used as diesel fuels, home heating oils, or used to generate electricity, sometimes right on the site of the waste disposal plant for use by the plant or sale into the grid. For more information about the tyre to oil technology, please visit https://kingtigergroup.com/tyre-to-fuel-recycling-plant/.

The Gas That Is Released Is Similar To Methane

Methane is the main ingredient of natural gas that’s delivered to homes and businesses for heating purposes. The gases released by the pyrolysis process are a mixture of mostly methane, propane and butane, but can be mixed into the regular natural gas pipeline and sold to homes. It is also a great fuel to be used in electrical power plants as well.

The Carbon Black The Is Left Is Easily Sold Back To Tire Manufacturers

The remaining carbon black is the same ingredient that tire and rubber manufacturers use when they make tires. It’s a commodity that is easy to sell and in demand. It can also be used in many other processes as a chemical ingredient and since it’s basically a free component of the pyrolysis waste it’s easy to sell.

If you have a plentiful supply of waste tires, plastics or oil, it would be a wise decision to check into making a profit by using tyre recycling to oil pyrolysis technology to break down your waste into usable, sellable commodities.