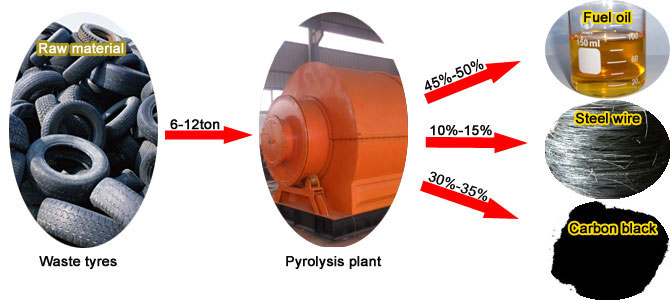

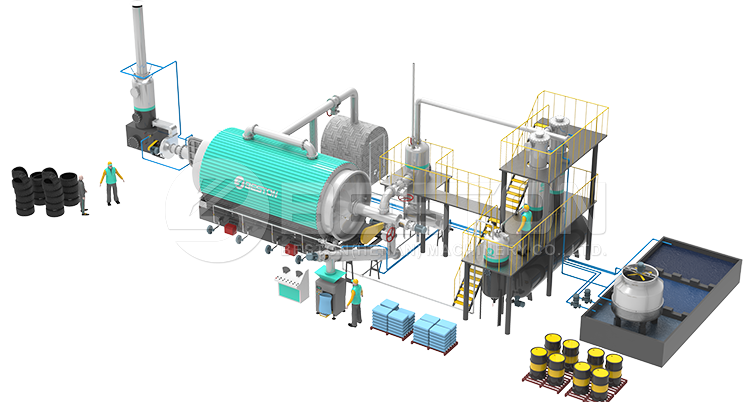

Tyre recycling can be a very lucrative business. Car owners need to change their tyres every few years. Very few of them find some use in the household for their used tyres. Most of the time, they want to get rid of used tyres. This creates a huge opportunity for entrepreneurs looking for an idea to bring them a nice profit. Recycling is one of the biggest trends of the moment. Besides, when you can use stuff nobody needs anymore to create new products that are in high demand, you can call yourself a winner. The scrap tyre pyrolysis plants are good choice for your investment.

The only issue is that a tyre recycling plant requires a big investment. Very few people are willing to invest their savings in something like this. One great idea is to try to find your plant somewhere else, where prices aren’t as high as in the US. You can try to find low tyre pyrolysis plant cost in China, and bring it over to the place where you need to install and operate it. This could save you a lot of money.

In order to find such equipment on the international market, you need to do some research work. Chances are you’re going to find some big business directories pretty quickly. Take a quick look into the industrial and recycling equipment and machines, and you may be able to find someone to sell you what you need. Since these directories target the US and other English speaking territories, chances are they are written in English, so you won’t need translation.

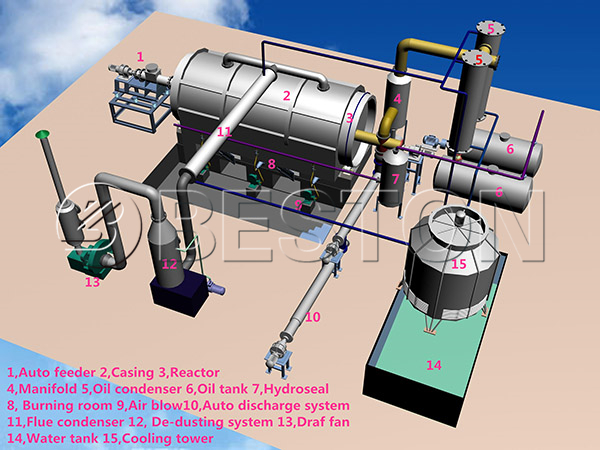

Once you have to names and the contact details of the seller, you need to contact them to find out the price of their equipment. Some of these companies will list their equipment with photos and lots of technical details. This will allow you to determine whether their machines match your specific requirements. If, for instance, you need to processing plant to provide 100% recycling of the old tyre, you’ll have to seek for this specific feature when you do your preliminary research.

As a general rule, you should try to find at least two or three vendors of the tyre recycling machine, and ask all of them for the price of the equipment: https://www.bestongroup.com/waste-tyre-pyrolysis-plant-suppliers/. This is how you can compare them, in order to choose the one that offers you the best value for money. When you send out your price inquiries, don’t forget to ask what these prices include. The transport costs of such heavy machines can add up to big amounts, so you have to know from the very beginning how much you’ll need to pay to buy a tyre recycling plant in China.

All these being said, you should know that China is an excellent market for used industrial equipment and heavy machinery. This is why smart entrepreneurs try to find equipment and spare parts on this market. As profit margins are rather small, they have to cut their costs without compromising on quality. Heading off to cheaper markets is the way to go. Read more of cost on such machine from Beston Group now.